340 - Tier 4 / Stage V

Cat® 340 Hydraulic Excavator

Cat® 340 hydraulic trackhoe excavators bring premium power, performance, control, digging, trenching, and heavy lifting capacity to your large scale projects.

DESCRIPTION

The Cat® 340 is evidence of our time-proven engineering and manufacturing know-how for top-notch quality, reliability, and durability. In addition to a powerful engine with millions of hours of service and reinforced booms and sticks for taking on hard and heavy work, the standard, heavy-duty reinforced undercarriage expertly absorbs the stress between jobsite terrain and machine. Built for rugged conditions, this rock-solid machine will help you turn payloads into profit.Stick Steer for Cat® Excavators

Latest Features

Cab Monitor Improvements

- Continuously improved user interface allows for intuitive navigation, minimizing performance interruption with the easy-to-use touchscreen menu.

- Identify apps quickly with a grid list view, abbreviated app names, and categorized menu options.

- A new notification center keeps important information visible to the operator, and displays messages without shrinking the camera view.

- Color coded notifications set critical messages apart from the rest.

- Use the in-monitor QR code to learn about machine technology and features through a full suite of "how-to" videos.

- Operator Coaching is an in-cab system that recognizes specific opportunities for operators to be more productive and prevent unnecessary machine wear and tear.

- After detecting inefficient or restricted actions, the system alerts the operator and provides insight into the inefficiency and steps to improve.

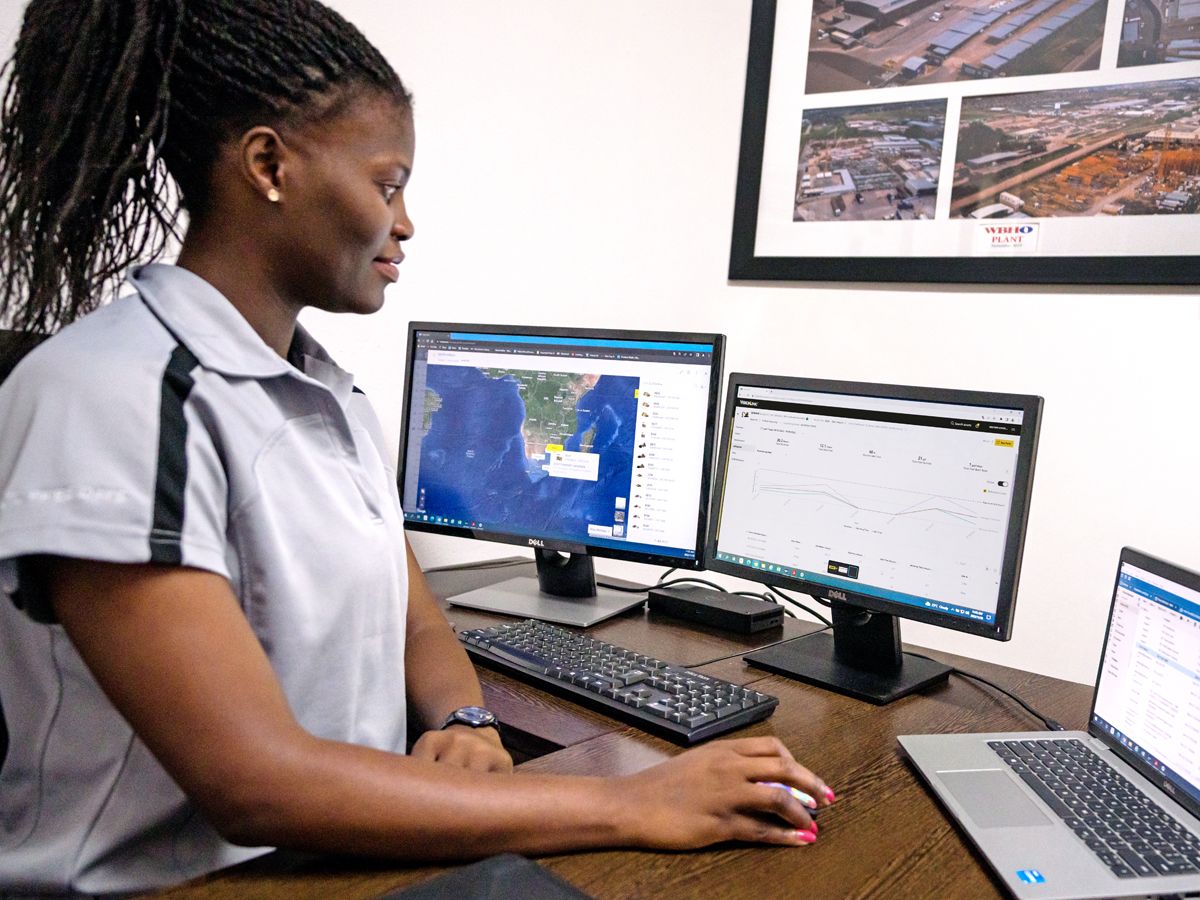

- Paired with a VisionLink Productivity subscription, this information and other Operator Coaching insights can be viewed from anywhere.

- Standard integrated vehicle health management system alerts the operator with service guidance and parts needed to enhance uptime.

- Enhance visibility to make service work easier and safer with optional inspection lighting.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area. Build Number: 08C

High Performance

Efficiency Through Technology

Take The Guesswork Out of Managing Your Equipment

Easy Maintenance

Dedicated Service and Superior Support

When you buy Cat® equipment, you get more than the machine. You’re also getting the support of a best-in-class dealer network backed by a range of flexible solutions, technology, tools, and more.

When you work with your local Cat dealer, you'll be supported by one of the industry's most extensive, knowledgeable dealer networks. Comprised of 160 independent dealers, the Cat Dealer Network serves 197 countries with thousands of branches around the globe.

It’s more uptime, cost-saving service and repair options, quality parts, and precision components. It’s all about support built around your success.

Ask your Cat dealer today about the many services that help you do your work your way.

- The importance of buying genuine Cat parts.

- Designed by Caterpillar engineers to the exact specs of your Cat equipment.

- Rigorously tested to ensure maximum performance.

- Covered by a 12-month warranty.

- Cat Inspect – Work made easy.

- Record real-time inspection data.

- Simplify inspections and reporting.

- Easy-to-read results all in one place.

- Cat Ground Engaging Tools (GET) – Longer wear. More work.

- GET for every machine and application.

- Tools to extend life and track GET lifecycles.

- Bucket rebuild options for optimal performance.

- Cat Hydraulic Components – Durability quality you can work with.

- Flexible options – New, reman, exchange, rebuild or repair.

- Expert diagnostics, testing, and contamination control.

- Buy in-store, online, or on your mobile device.

- Cat Hose Service – Fast, safe—to get you back to work.

- Hoses and couplings for most makes and models.

- OEM database ensures an exact fit.

- Industry-best tooling, training, and assembly standards.

- Cat Certified Rebuild – An investment that works. Again, and again.

- Better-than-when-new performance at a fraction of the cost.

- Performance, safety, and technology upgrades and enhancements.

- Full warranty coverage, Customer Value Agreement, and special financing.

- Cat Remote Services – Work done in a flash.

- Cut downtime for updates and service.

- Install the latest machine software remotely.

- Troubleshoot issues before a technician arrives.

Get industry-leading support for any question or problem you have 24 hours a day, 7 days a week, 365 days a year.

Learn more at https://parts.cat.com/

Work in Comfort

Safely Home Every Day

Simple to Operate

Sustainability

**Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

340 Variable Angle Boom Configuration

The Cat® 340 Variable Angle Boom 6.6m (21'8") (VAB) provides one extra articulation to maximize your application range while minimizing the space required to rotate in tight earthmoving and demolition sites, allowing you to work closer to the machine.

On-Board Cat Technology Helps Increase Efficiency

- This configuration is equipped with standard Cat technologies, including Standard Grade Assist, Cat Payload, and 2D E-Fence, which boosts operating efficiency through technology and is compatible with VisionLink®, Cat PL161 attachment locator, Remote Troubleshoot, Remote Flash, and Cat Inspect, allowing you to eliminate the guesswork in managing your equipment.

- Cat Grade Assist for excavators automates boom and stick movements for more accurate cuts with less effort. It uses machine position sensors and operator-defined depth and slope parameters to enable single-lever digging, helping improve efficiency.

- Cat Payload helps you achieve precise load targets to improve your operating efficiency. Pick up a load of material--with a bucket and thumb combination or grapple and clamshell attachments--and get a real-time weight estimate without swinging.

- The 2D E-Fence prevents the excavator from moving outside operator-defined set points. The system works with thumb and bucket combinations, hammer, grapple, and clamshell attachments.

Demolition Cab Compatibility

- For demanding demolition sites, the 340 VAB is compatible with the optional demolition cab that tilts up to 30° for a more productive and comfortable sight line.

- The front windshield and roof window are made with EN 356 P5A glazing for enhanced impact resistance and have one-piece parallel wipers with three intermittent settings and washer spray.

- Standard Operator Protective Guards (OPG) help protect the roof and front reinforced EN356 P5A laminated windows from falling debris during demolition while helping to maintain visibility on the jobsite.

- The optional demolition cab features a larger premium heated and cooled seat with a 254 mm (10 in) high-resolution touchscreen monitor. The monitor allows operators to view the active stability monitoring system, which gives audible and visual alerts when the work tool's position approaches its stability limit.

- Get in and out of the cab with ease using the tip-up left console.

- Control the excavator comfortably with easy-to-reach controls located in front of you.

- Stow your gear with plenty of in-cab storage beneath and behind the seat, overhead, and in the consoles.

- Use the standard radio’s USB ports and Bluetooth® technology to connect personal devices and make hands-free calls.

- Rearview and side-view cameras are standard. You can also upgrade to 360° visibility to view objects and personnel around the machine in a single view.

- Grease sealed between track pins and bushings reduces travel noise and prevents debris from entering to increase undercarriage life.

The 340 VAB configuration is available for Europe only.

- Standard Equipment

- Optional Equipment

- Specs

- Docs

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- CAT TECHNOLOGY

- VisionLink®

- Remote Flash

- Remote Troubleshoot

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability to install 3D grade systems from Trimble, Topcon, and Leica

- Cat Grade 2D

- Cat Assist

- Cat Payload

- Auto hammer stop

- Work tool recognition (PL161)

- Work tool tracking (PL161)

- ELECTRICAL SYSTEM

- Maintenance-free 1,000 CCA batteries (x2)

- Centralized electrical disconnect switch

- LED exterior chassis and boom lights

- ENGINE

- Three selectable modes: Power, Smart, Eco

- Auto engine speed control

- - 18° C (0° F) cold start capability

- Double element air filter with integrated pre-cleaner

- Remote disable

- HYDRAULIC SYSTEM

- Boom and stick regeneration circuit

- Electronic main control valve

- Auto heavy lift

- Auto dig boost

- Auto hydraulic oil warmup

- Bio hydraulic oil capability

- Fine swing

- Reverse swing damping valve

- Auto swing parking brake

- High performance hydraulic return filter

- Two speed travel

- SAFETY AND SECURITY

- Cat E-Fence

- Caterpillar One Key security system

- Lockable external tool / storage box

- Lockable door, fuel, and hydraulic tank locks

- Lockable fuel drain compartment

- Lockable disconnect switch

- Service platform with anti-skid plate & recessed bolts

- RH handrail and handhold

- Signaling / warning horn

- Ground-level secondary engine shutoff switch

- Rearview camera

- Inspection Lighting

- SERVICE AND MAINTENANCE

- Integrated vehicle health management system

- Grouped location of engine oil & fuel filters

- Sampling ports for Scheduled Oil Sampling (S·O·S℠)

- UNDERCARRIAGE AND STRUCTURES

- Towing eye on base frame

- Swivel guard

- HD bottom guard

- HD travel motor guards

- Grease lubricated track

- HD swing frame

- HD swing bearing

- 7.56 mt (16,667 lb) counterweight

- DELUXE CAB

- High-resolution 203 mm (8") LCD touchscreen monitor

- Auto bi-level air conditioner

- Jog dial and shortcut keys for monitor control

- Keyless push-to-start engine control

- Height-adjustable console

- Tilt-up left-side console

- Heated air-suspension seat

- Monitor integrated Bluetooth radio with USB/Aux ports

- 12V DC outlets

- Document storage

- Overhead storage and rear storage with nets

- Beverage holder

- Cup holder

- Openable two-piece front window

- Rear window emergency exit

- Radial wiper with washer

- Openable polycarbonate skylight hatch

- LED dome light

- Floor welcome light

- Roof sunscreen

- Roller front sunscreen

- Washable floor mat

- Beacon ready

- PREMIUM CAB

- High-resolution 254 mm (10") LCD touchscreen monitor

- Auto bi-level air conditioner

- Jog dial and shortcut keys for monitor control

- Keyless push-to-start engine control

- Height-adjustable console

- Tilt-up left-side console

- Heated and ventilated air-suspension seat

- Monitor integrated Bluetooth radio with USB/Aux ports

- 12V DC outlets

- Document storage

- Overhead storage and rear storage with nets

- Beverage holder

- Cup holder

- Openable two-piece front window

- Rear window emergency exit

- Parallel wiper

- Openable polycarbonate skylight hatch

- LED dome light

- Floor welcome light

- Roof sunscreen

- Roller front sunscreen

- Washable floor mat

- Beacon ready

Optional Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- BOOMS AND STICKS

- 6.18 m (20'3") Mass boom

- 6.5 m (21'4") HD Reach boom

- 2.55 m (8'4") Mass stick

- 2.8 m (9'2") HD Reach stick

- 3.2 m (10'6") HD Reach stick

- 3.9 m (12'10") HD Reach stick

- TB family bucket linkage with/without lifting eye

- DB family bucket linkage with/without lifting eye

- CAT TECHNOLOGY

- Cat Grade Connectivity

- Cat Grade 2D with Attachment Ready Option (ARO)

- Cat Grade with 3D single GNSS

- Cat Grade with 3D dual GNSS

- Cat Tilt Rotator (TRS) Integration

- Operator Coaching

- ELECTRICAL SYSTEM

- Maintenance-free 1,000 CCA batteries (x4)

- ENGINE

- Oil level sensor

- Battery-operated engine heater

- Cold start block heater

- 52°C (126°F) high-ambient cooling

- Hydraulic reverse fan

- -32°C (-25°F) cold start capability

- HYDRAULIC SYSTEM

- Single one-way circuit

- Combined two-way circuit

- Hydraulic efficiency monitoring

- SAFETY AND SECURITY

- Cat Detect - People Detection

- Cat Command remote control

- Swing alarm

- Boom lowering check valve

- Stick lowering check valve

- UNDERCARRIAGE AND STRUCTURES

- Full-length track guiding guards

- Segmented two-piece track guiding guards

- HD rollers

- 600 mm (24") double grouser, triple grouser, HD triple grouser track shoes

- 700 mm (28") triple grouser track shoes

- 800 mm (31") triple grouser track shoes

- 850 mm (33") triple grouser track shoes

- DELUXE CAB

- High-resolution 254 mm (10") LCD touchscreen monitor

- Roller rear sunscreen

- Cat Stick Steer

- Auxiliary relay

- PREMIUM CAB

- One-piece front windshield

- Cat Stick Steer

- Auxiliary relay

Specs

Overview

Engine

Hydraulic System

Swing Mechanism

Weights

Service Refill Capacities

Dimensions

Working Ranges and Forces

Air Conditioning System

- 340 Excavator - Product Brochure (EU, Aus-NZ, N Am, South Korea, Turkey) (pdf)

- 340 Excavator - Technical Specifications (Europe) (pdf)

- 340 Excavator - Technical Specifications (Japan) (pdf)

- 340 Excavator -Technical Specifications (N Am) (pdf)

- 340 Excavator -Technical Specifications (ANZ) (pdf)

- 340 Excavator -Technical Specifications (Turkey) (pdf)

SEE HOW 340 – Tier 4 / Stage V COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Cat

- Status

- Current

- Net Power - ISO 9249

- 346 hp / 258.3 kW

- Engine Model

- Cat C9.3B

- Bore

- 5 in / 115 mm

- Stroke

- 6 in / 149 mm

- Displacement

- 568 in³ / 9.3 l

- Biodiesel Capability

- Up to B20¹

- Emissions

- Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- Note (1)

- Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,000 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture.

- Note (2)

- ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

- Maximum Pressure - Equipment

- 5076 psi / 35000 kPa

- Maximum Pressure - Travel

- 5076 psi / 35000 kPa

- Maximum Pressure - Swing

- 4264 psi / 29400 kPa

- Swing Speed

- 8.84 r/min / 8.84 r/min

- Operating Weight

- 83100 lb / 37700 kg

- Fuel Tank Capacity

- 158.5 gal (US) / 600 l

- Cooling System

- 10.5 gal (US) / 40 l

- Engine Oil

- 8.5 gal (US) / 32 l

- Final Drive - Each

- 2.1 gal (US) / 8 l

- Hydraulic System - Including Tank

- 98.5 gal (US) / 373 l

- Hydraulic Tank

- 42.5 gal (US) / 161 l

- DEF Tank

- 21.1 gal (US) / 80 l

- Boom

- Reach 6.5 m (21'4")

- Stick

- Reach 3.9 m (12'10")

- Bucket

- HD 2.36 m³ (3.08 yd³)

- Counterweight Clearance

- 4.2 ft / 1260 mm

- Ground Clearance

- 1.8 ft / 510 mm

- Track Length to Center of Rollers

- 13.3 ft / 4040 mm

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.00 kg of refrigerant, which has a CO2 equivalent of 1.430 metric tonnes.

- Brand

- Cat

- Status

- Current

- Net Power - ISO 9249

- 300 hp / 223.5 kW

- Engine Model

- Cat C7.1 TTA

- Bore

- 4 in / 105 mm

- Stroke

- 5 in / 135 mm

- Displacement

- 428 in³ / 7.01 l

- Biodiesel Capability

- Up to B20¹

- Emissions

- Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- Note (1)

- Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,000 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture.

- Note (2)

- ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

- Maximum Pressure - Equipment

- 5076 psi / 35000 MPa

- Maximum Pressure - Travel

- 5076 psi / 35000 MPa

- Maximum Pressure - Swing

- 4264 psi / 29400 MPa

- Swing Speed

- 8.84 r/min / 8.84 r/min

- Operating Weight

- 81100 lb / 36800 kg

- Fuel Tank Capacity

- 158.5 gal (US) / 600 l

- Cooling System

- 10.2 gal (US) / 39 l

- Engine Oil

- 6.6 gal (US) / 25 l

- Final Drive - Each

- 2.1 gal (US) / 8 l

- Hydraulic System - Including Tank

- 98.5 gal (US) / 373 l

- Hydraulic Tank

- 42.5 gal (US) / 161 l

- DEF Tank

- 13.2 gal (US) / 50 l

- Boom

- Reach 6.5 m (21'4")

- Stick

- Reach 3.9 m (12'10")

- Bucket

- HD 2.00 m³ (2.61 yd³)

- Counterweight Clearance

- 4.2 ft / 1260 mm

- Ground Clearance

- 1.8 ft / 510 mm

- Track Length to Center of Rollers

- 13.3 ft / 4040 mm

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.00 kg of refrigerant, which has a CO2 equivalent of 1.430 metric tonnes.

- Brand

- Caterpillar

- Status

- Current

- Net Power - ISO 9249

- 413 hp / 308 kW

- Engine Model

- C9.3 B

- Bore

- 5 in / 115 mm

- Stroke

- 6 in / 149 mm

- Displacement

- 568 in³ / 9.3 l

- Biodiesel Capability

- Up to B20¹

- Emissions

- Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

- Note (1)

- Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 1,800 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture.

- Note (2)

- ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

- Maximum Pressure - Equipment

- 5076 psi / 35000 kPa

- Maximum Pressure - Travel

- 5076 psi / 35000 kPa

- Maximum Pressure - Swing

- 3727 psi / 25700 kPa

- Swing Speed

- 7.94 r/min / 7.94 r/min

- Operating Weight

- 105100 lb / 46000 kg

- Fuel Tank Capacity

- 179.6 gal (US) / 680 l

- Cooling System

- 12.7 gal (US) / 48 l

- Engine Oil

- 8.5 gal (US) / 32 l

- Final Drive - Each

- 2.9 gal (US) / 11 l

- Hydraulic System - Including Tank

- 145.3 gal (US) / 550 l

- Hydraulic Tank

- 57.3 gal (US) / 217 l

- DEF Tank

- 21.1 gal (US) / 80 l

- Boom

- Reach 6.9 m (22'8")

- Stick

- Reach 3.9 m (12'10")

- Bucket

- GDC 3.08 m³ (4.03 yd³)

- Counterweight Clearance

- 4.5 ft / 1340 mm

- Ground Clearance

- 1.8 ft / 520 mm

- Track Length to Center of Rollers

- 14.4 ft / 4360 mm

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.00 kg of refrigerant, which has a CO2 equivalent of 1.430 metric tonnes.