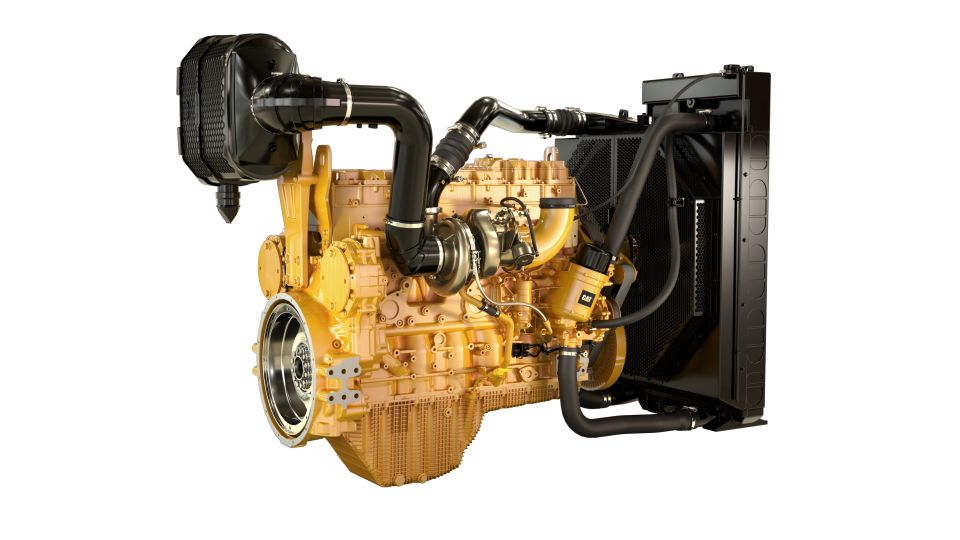

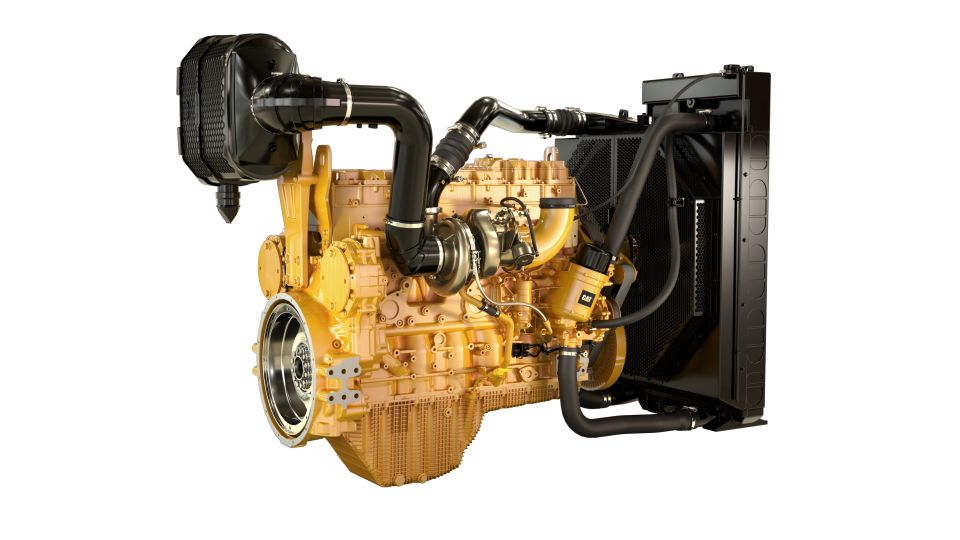

C13D

C13D Industrial Power Unit LRC

DESCRIPTION

The Cat® C13D IPU configuration not only provides the flexibility and options found on a standard industrial engine, but also comes fitted with an integrated cooling system, an on-engine fuel filtration module, as well as full wire harnessing leading to an engine-mounted ECM. Meeting UN ECE R96 Stage IIIA, Brazil Mar-1, and other equivalent emission standards, the IPU allows for easier and faster installation, allowing the customer to spend more time doing the work that matters.Full Packaged Installation

The IPU is an example of an industrial configuration that has the cooling pack, the fuel filter module, and the entire wiring harness all pre-mounted on the engine right out of the factory. Furthermore, a control panel and telematics unit can be added on for an even more complete package.

Reliable, Quiet and Durable Power

A quiet engine is not only safer, but it also cuts down on job site noise pollution – especially in areas where decibel limitations are enforced. With proven technologies such as rear gear train architecture and high-pressure common rail fuel injection, your Cat® powered equipment is made to run quietly while you work.

Ideal Applications

Industrial, agricultural and construction applications such as:

• compressors

• trenchers

• chippers

• grinders

• irrigation equipment

• bore rigs

• drill rigs

• pumps

• hydraulic power units.

The C13D has high ambient and altitude and low cold start capability so is suitable for use in applications where there are harsher climates.

Cat Dealer Product Support

Our network of Cat dealers across the globe means no matter where you are, help is close by. And because our engines are covered by warranty, you can feel good about your purchase being protected. With programs like extended service coverage and customer value agreements, you can choose to continue your Cat engine’s protection for the life of your machine.

Safety

At Caterpillar, safety is a priority. It's why we put all our engines through rigorous rounds of testing and validation. We make our engines reliable, so operators can focus on keeping their work site safe, secure and in service.

- Standard Equipment

- Optional Equipment

- Specs

- Docs

Standard Equipment

- Air Inlet System

- Wastegated turbocharger

- Air-to-Air Aftercooled

- Front or rear exhaust configurations available

- Control System

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Integrated Electronic Control Unit (ECU)

- Remote fan control

- Cooling System

- Fluids module, which includes: water pump, oil cooler, top-service cartridge oil filter (optional), dual coolant thermostats, and single oil thermostat

- Centrifugal water pump

- Guidance on cooling system design available through your dealer to ensure equipment reliability

- Remote oil filter variant of the fluids module available

- Flywheel and Flywheel Housing

- Multiple Flywheel Housing configurations, featuring a basic, standard and heavy duty PTO setup

- Standard SAE No. 1 flywheel housing with SAE No. 14 or 140 flywheels

- Fuel System

- Common rail direct injection fuel system with zero-static leak injectors

- Fuel module, which includes: primary and secondary cartridge filters, and a manual or electric priming pump

- Remote fuel module available

- Fuel manifold which allows for outboard or rearward fuel return-to-tank plumbing, as well as coolant supply

- Oil-lubricated high pressure fuel and mechanical fuel transfer pump combination

- Lube System

- No-service-needed passive open crankcase ventilation filtration system built into the valve cover

- No-mess service oil filter drainback feature built into fluids module

- Oil filler

- Oil level sensor

- Oil dipstick

- Gear-driven oil pump

- Choice of front, rear or center sumps

- Open crankcase ventilation system with fumes disposal

- Power Take Off (PTO)

- Up to 5 additional power take-offs: 2 rear facing (SAE B, C, or D), 2 forward-facing (SAE A or SAE B), and an additional low-mount forward-facing (SAE B)

- General

- Caterpillar yellow paint, with optional colors available on request

- Vibration damper

- Lifting eyes

Optional Equipment

- Industrial Power Unit

- Factory-installed cooling pack which includes the radiator, the air-to-air aftercooler (ATAAC), coolant lines to and from the radiator, and air lines to and from the ATAAC.

- Factory-installed engine-mounted aftertreatment system, pre-connected exhaust air lines, and air cleaners

- Factory-installed instrument / control panels embedded with telematics units

Specs

Overview

Power Rating

Emission Standards

General

Engine Dimensions*

SEE HOW C13D COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Cat

- Status

- Current

- Maximum Power

- 690 hp / 515 kW

- Rated Speed

- 1800-2100 rpm

- Minimum Power

- 456 hp / 340 kW

- Emissions

- UN ECE R96 Stage IIIA, Brazil Mar-1, Unregulated

- Engine Configuration

- In-Line 6

- Bore

- 5.1 in / 130 mm

- Stroke

- 6.4 in / 162 mm

- Displacement

- 787.2 in³ / 12.9 l

- Compression Ratio

- 16.5:1

- Aspiration

- Turbocharged-Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

- Length

- 89 in / 2249 mm

- Width

- 46 in / 1160 mm

- Height

- 65 in / 1641 mm

- Brand

- Caterpillar

- Status

- Current

- Maximum Power

- 577 hp / 430 kW

- Rated Speed

- 1800-2100 rpm

- Minimum Power

- 456 hp / 340 kW

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- Engine Configuration

- Inline 6, 4-Stroke-Cycle Diesel

- Bore

- 5.1 in / 130 mm

- Stroke

- 6.2 in / 157 mm

- Displacement

- 762.8 in³ / 12.5 l

- Compression Ratio

- 15.8:1

- Aspiration

- Turbocharged Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

- Length

- 79 in / 2002 mm

- Width

- 46 in / 1160 mm

- Height

- 71 in / 1801 mm

- Brand

- Caterpillar

- Status

- Current

- Maximum Power

- 690 hp / 515 kW

- Rated Speed

- 1800-2100 rpm

- Minimum Power

- 456 hp / 340 kW

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- Engine Configuration

- In-Line 6

- Bore

- 5.1 in / 130 mm

- Stroke

- 6.4 in / 162 mm

- Displacement

- 787.2 in³ / 12.9 l

- Compression Ratio

- 18:1

- Aspiration

- Turbocharged-Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

- Length

- 89 in / 2249 mm

- Width

- 46 in / 1160 mm

- Height

- 65 in / 1641 mm