HM210

HM210 Mulcher

DESCRIPTION

High-performance cutting and mulching of vegetation and overgrowth.Cat® Mulchers for Skid Steer Loaders and Compact Track Loaders are designed for high-performance cutting and mulching vegetation and undergrowth from forested terrain. The hydraulic mulcher reduces saplings, shrubs and trees into mulched material, making it ideal for environmental maintenance, such as creating fire lanes. Other applications include land reclamation, foliage removal from building construction sites, and shredding pruned material and organic waste for biomass production.Cat® Mini Excavator Mulcher at Work

Cat® Mini Excavator Mulcher Maintenance Tips

Cat® Mini Excavator Mulcher Overview

An Attachment for Every Job - Cat® Work Tool Attachments

Application

Use Mulchers for brush clearing, vegetation management, reclaiming untitled land, environmental maintenance, shredding pruned material and organic waste for biomass production.

Variable Displacement Piston Motor

When motor pressure approaches a stall condition, the motor displacement will change to provide high torque at low speed to power through material with reduced risk of stalling. The motor automatically switches the displacement back for high speed operation once the material is cleared.

Balanced Drum

Mulching drum weighted for maximum mulching performance and smooth operation. Staggered tooth design allows for only one tooth to contact material at all times for efficient cutting performance.

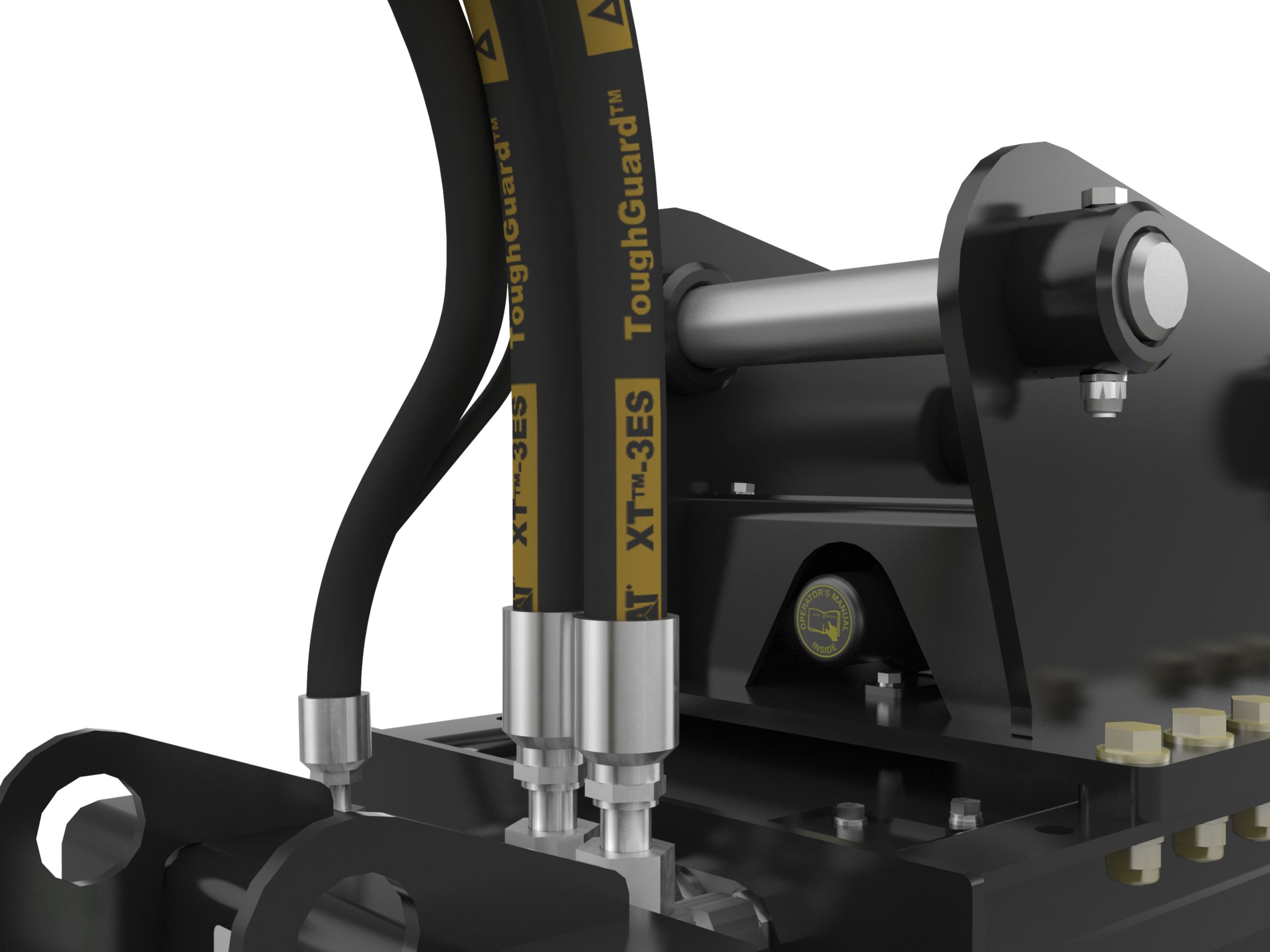

Cat® XTC Hydraulic Hoses

Quick disconnect hydraulic lines allow for easy tool swapping. Case drain line improves motor life and protects internal motor components. Spiral wrapped hose protection helps protects the hydraulic lines during use.

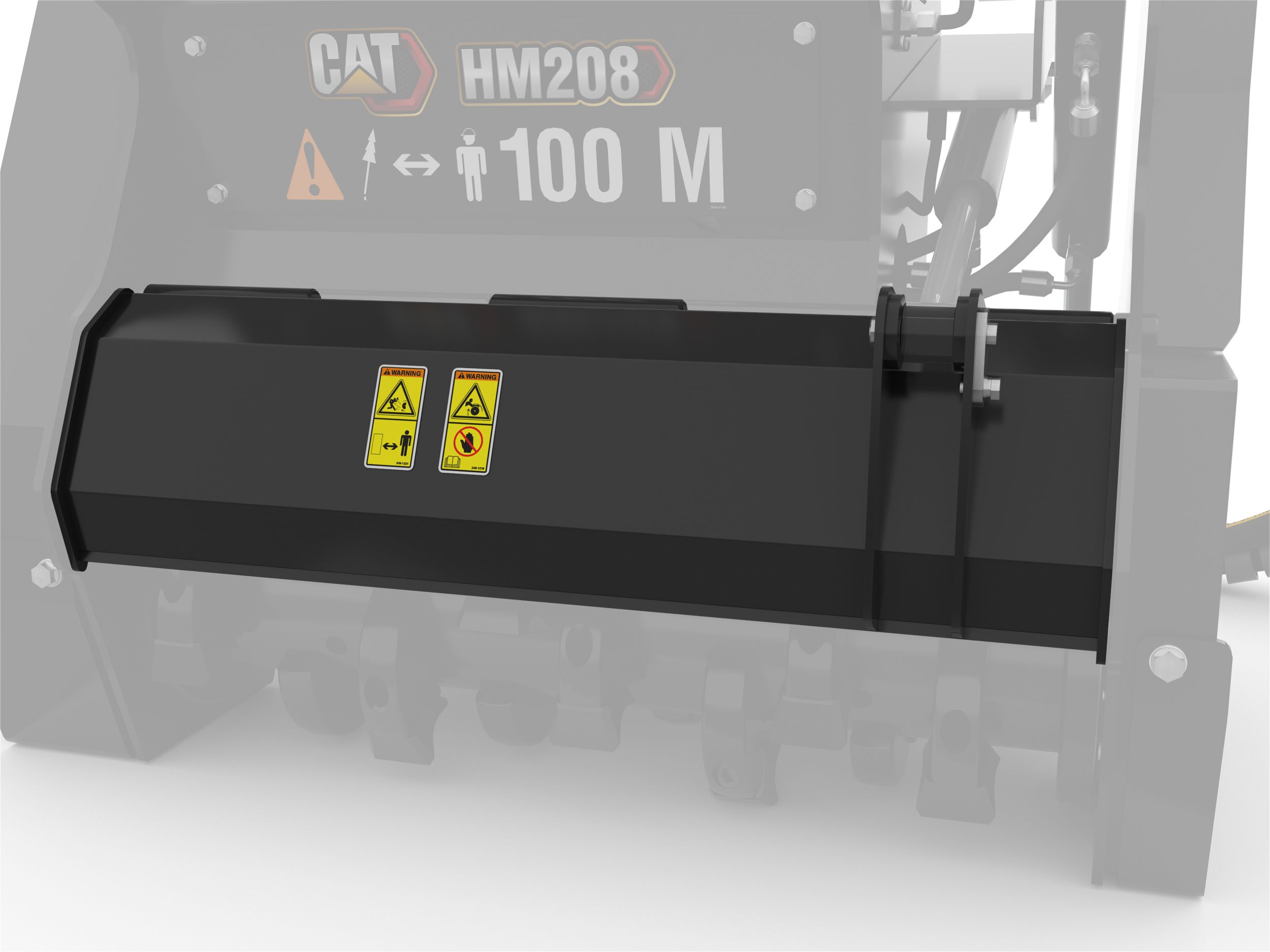

Dual Hydraulic Doors

Standard dual hydraulic doors (front and back) allow for debris to be recirculated through drum longer for a finer finished product.

Integrated Stand

Integrated stand eases access for attachment and removal. Allows mulcher to sit flat for storage.

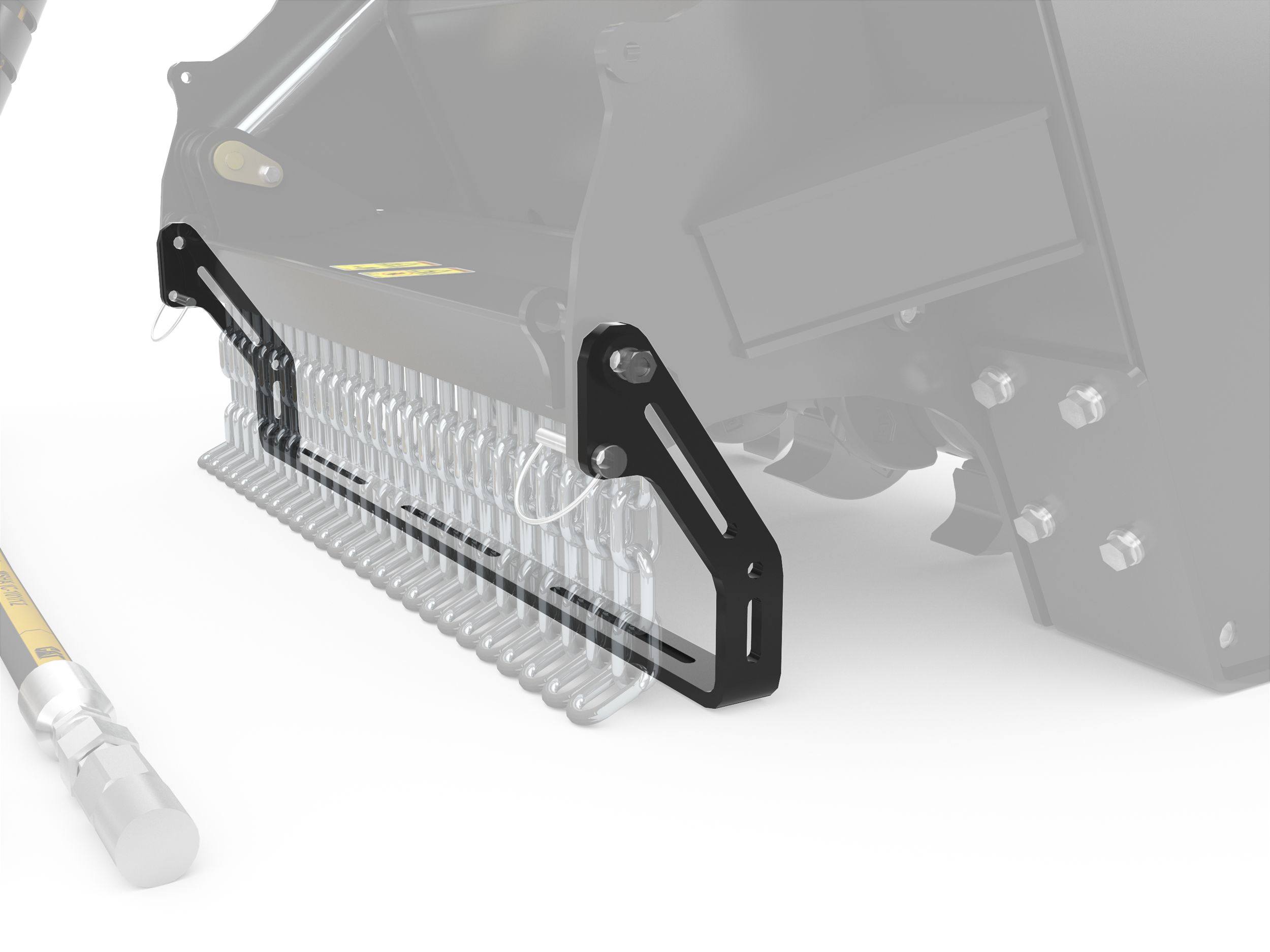

Rear Chain Guard

Rear chain guard limits the amount of debris thrown behind the machine.

Bolt-On Replaceable Skid Shoes

Bolt-On replaceable skid shoes are reinforced and built to last, yet easily replaceable as needed.

Tool Mounted Operation and Maintenance Manual Holder

Tool mounted and sealed from the elements, this holder includes all of the operation manuals and maintenance guides required for proper operation of the work tool.

- Specs

- Docs

Specs

Overview

SEE HOW HM210 COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Cat

- Status

- Current

- Overall Width

- 48.3 in / 1226 mm

- Working Width

- 39.8 in / 1012 mm

- Length

- 28.1 in / 714 mm

- Overall Height

- 41.9 in / 1065 mm

- Weight

- 1190.5 lb / 540 kg

- Drive Method

- V-Belt Drive

- Motor

- Dual Speed Axial Piston

- Required Hydraulics

- Standard Flow

- Optimal Hydraulic Flow

- 70-130 L/min (18-34 gpm)

- Optimal Hydraulic Pressure

- 150-250 bar (2175-3626 psi)

- Drum Speed

- 2770-2890 RPM

- Fixed Teeth per Drum

- 24

- Maximum Cutting Diameter

- 120-200 mm (5-8 in)

- Brand

- Cat

- Status

- Current

- Overall Width

- 40.4 in / 1026 mm

- Working Width

- 32.2 in / 818 mm

- Length

- 28.1 in / 714 mm

- Overall Height

- 41.9 in / 1065 mm

- Weight

- 1080.3 lb / 490 kg

- Drive Method

- V-Belt Drive

- Motor

- Dual Speed Axial Piston

- Required Hydraulics

- Standard Flow

- Optimal Hydraulic Flow

- 70-130 L/min (18-34 gpm)

- Optimal Hydraulic Pressure

- 150-250 bar (2175-3626 psi)

- Drum Speed

- 2770-2890 RPM

- Fixed Teeth per Drum

- 15

- Maximum Cutting Diameter

- 120-200 mm (5-8 in)

- Brand

- Cat

- Status

- Current

- Overall Width

- 69.2 in / 1758 mm

- Working Width

- 58.3 in / 1480 mm

- Length

- 48 in / 1219 mm

- Overall Height

- 50.4 in / 1281 mm

- Weight

- 1803.4 lb / 818 kg

- Drive Method

- V-Belt

- Motor

- Axial Piston Dual Speed

- Required Hydraulics

- High Flow

- Optimal Hydraulic Flow

- 96-117 L/min (25-31 gpm)

- Optimal Hydraulic Pressure

- 200-230 bar (2900-3336 psi)

- Drum Speed

- 2480-3020 RPM

- Fixed Teeth per Drum

- 36

- Maximum Cutting Diameter

- 7.9 in / 200 mm