TRS4

TRS4 Tiltrotator

DESCRIPTION

Cat® Tiltrotators help you maneuver obstacles in your work area without the need for repositioning your machine.Cat® Tiltrotators for excavators provide 360-degree rotation and 40-degree tilting action side-to-side, allowing the machine to reach more work areas from a single position. The tiltrotator enables the operator to maneuver around posts, rocks, and other obstacles, as well as to reach along ditch edges more easily.Cat® Tiltrotator System

Cat® Tiltrotator System Overview

Cat® TRS Tiltroator Display and Settings

Cat® TRS6 Tiltrotator and Bucket at Work

Cat® TRS6 Tiltrotator and Grapple at Work

Advantages of the Cat® TRS8 Tiltrotator

Cat® TRS8 Tiltrotator at Work

The Cat® TRS Tiltrotator

Cat® 306 Mini Excavator with Cat TRS6 Tiltrotator

An Attachment for Every Job - Cat® Work Tool Attachments

Complete 360 Degree Rotation

Provides optimal control of your work tools to provide greater flexibility.

Integrated Central Lubrication System

A single point of entry for grease allows the entire unit to be greased quickly and easily.

Oil Filled Gearbox

A maintenance free solution that more effectively distributes heat, providing better lubrication than grease.

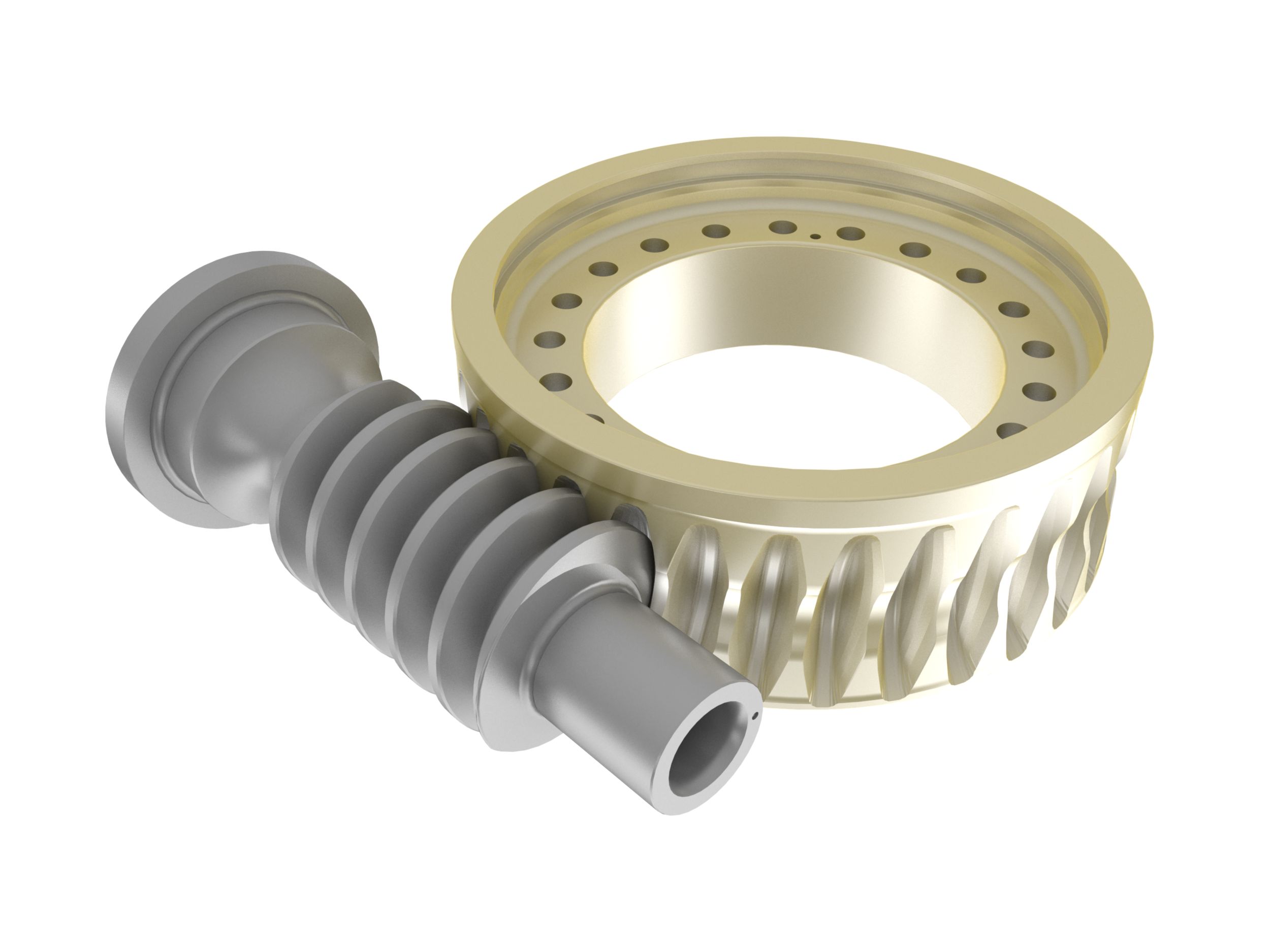

Heavy Duty Worm Gear

Worm gear box with high rotation torque and self locking ability allows digging in all directions with full power, allowing the gear to accept the maximum machine forces and split the load through the entire TRS construction.

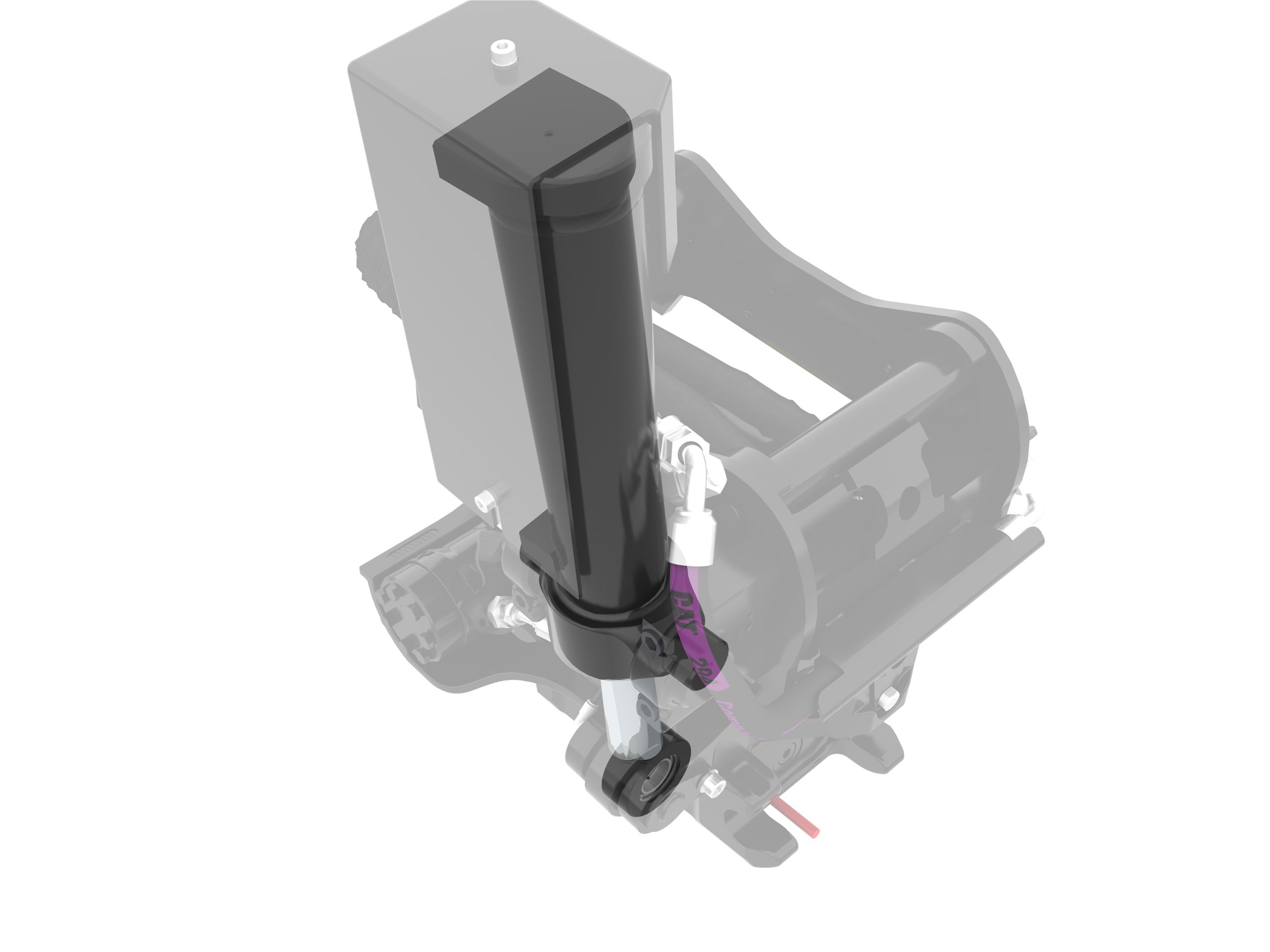

Double Acting Cylinder with Load Hold Valve

Valves sustain holding pressures and prevent cylinder movement under load constraints.

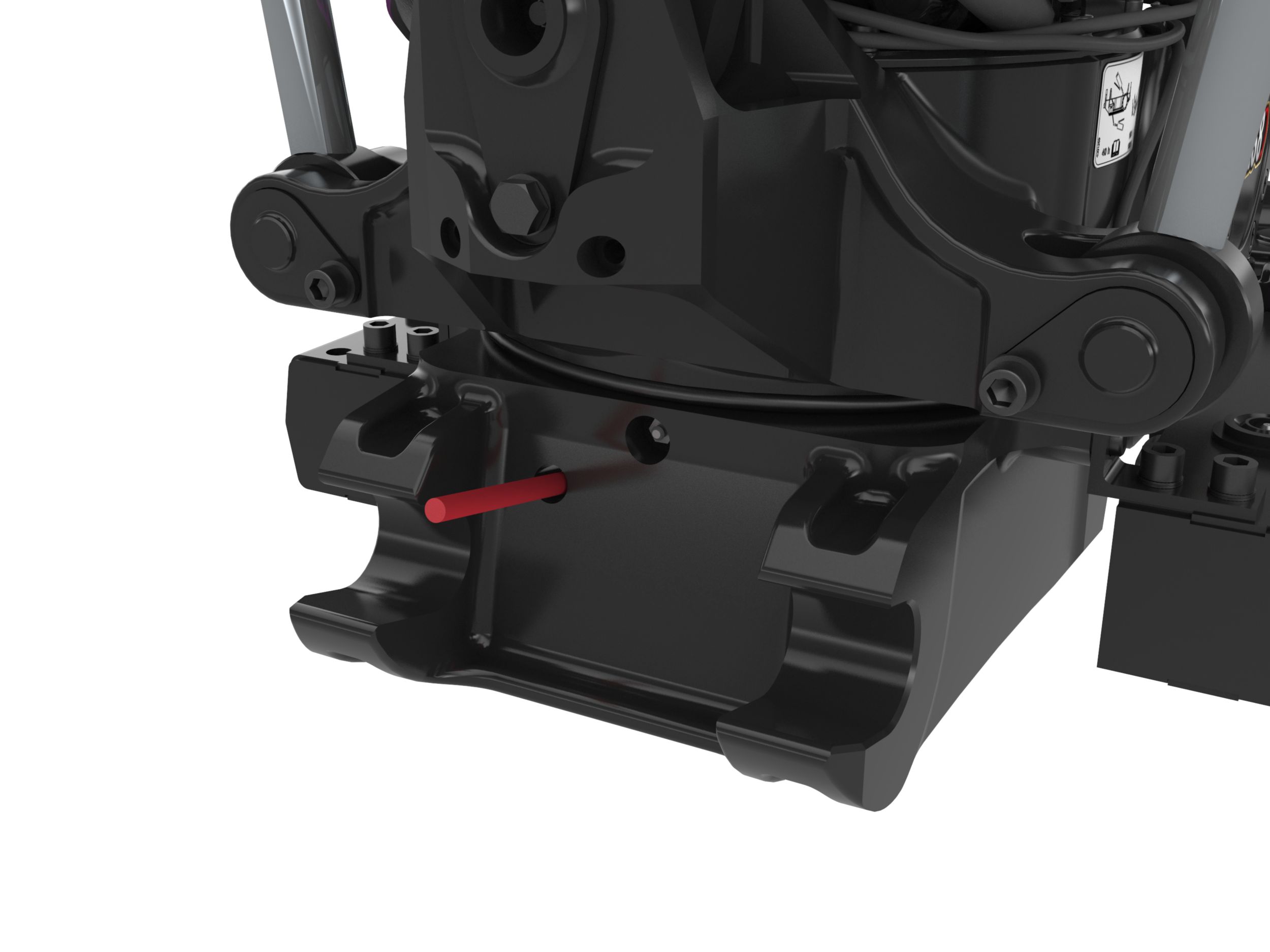

Visual Verification Indicator

The visual verification indicator allows the operator to visibly confirm, from the cab, that the coupler has successfully locked the attachment into place properly.

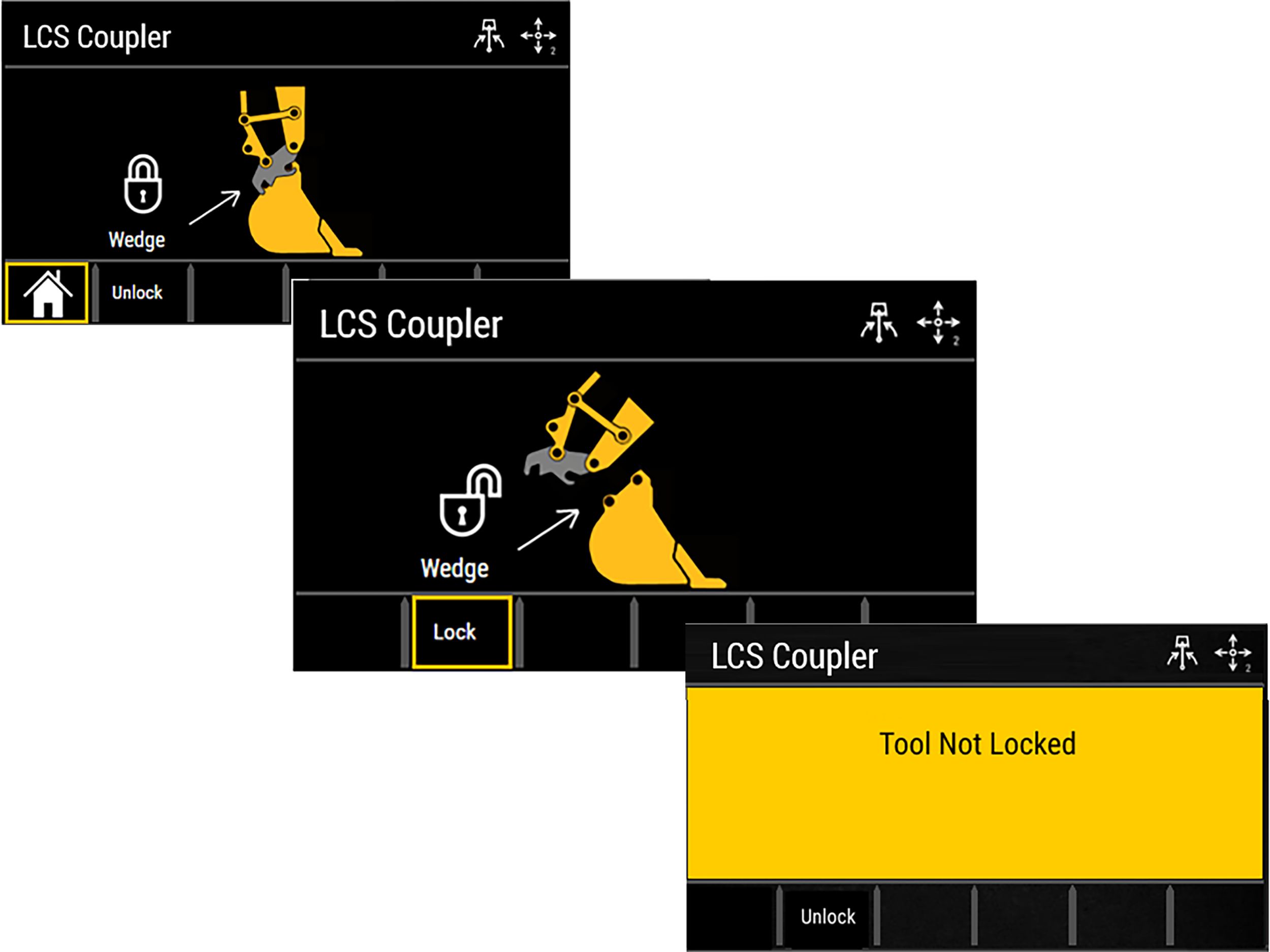

Locking Control System (LCS)

LCS incorporates an electronic position sensor integrated into the quick coupler hydraulic cylinder. This sensor provides precise and reliable input to an electronic processor mounted inside the quick coupler. This microprocessor provides digital communication to the Next Generation MHE machine Electronic Control Module (ECM) by way of an electrical harness. This data is then displayed on the operators display screen, and will provide audible indications when that locking status changes.

Compatibility Note

Only compatible with the following Next Gen machines and serial numbers:

- 302.7 - S/N CZ6 1 & Up

- Specs

- Docs

Specs

Overview

SEE HOW TRS4 COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Cat

- Status

- Current

- Machine Class

- 2 Ton Mini Excavator

- Interface Options: Top-Bottom

- Pin On / Pin Grabber

- Rotation Speed

- 7 Seconds per 1 full rotation

- Tilt Angle Range +/-

- 40° Left/Right

- Maximum Bucket Capacity

- 3.9 ft³ / 110 l

- Maximum Bucket Width

- 39.4 in / 1000 mm

- Optimal Hydraulic Flow

- 17-25 L/min (4.5-6.7 gpm)

- Maximum Operating Pressure

- 3045.8 psi / 21000 kPa

- Tilting Torque

- 4277.9 lb/ft / 5800 N·m

- Turning Torque

- 1253.9 lb/ft / 1700 N·m

- Brand

- Caterpillar

- Status

- Current

- Machine Class

- 23-35

- Interface Options: Top-Bottom

- HCS80 / S80

- Rotation Speed

- 8 seconds, per 1 full rotation

- Tilt Angle Range +/-

- 40° Left/Right

- Maximum Bucket Capacity

- 2.09 yd³ / 1.6 m³

- Maximum Bucket Width

- 79 in / 2000 mm

- Optimal Hydraulic Flow

- 134 L/min (35 gpm)

- Maximum Operating Pressure

- 3626 psi / 25000 kPa

- Tilting Torque

- 47720 lb/ft / 64700 N·m

- Turning Torque

- 8806 lb/ft / 11940 N·m

- Brand

- Cat

- Status

- Current

- Machine Class

- 2 Ton Mini Excavators

- Interface Options: Top-Bottom

- Pin On / S40

- Rotation Speed

- 7 Seconds per 1 full rotation

- Tilt Angle Range +/-

- 40° Left/Right

- Maximum Bucket Capacity

- 3.9 ft³ / 110 l

- Maximum Bucket Width

- 39.4 in / 1000 mm

- Optimal Hydraulic Flow

- 17-25 L/min (4.5-6.7 gpm)

- Maximum Operating Pressure

- 3045.8 psi / 21000 kPa

- Tilting Torque

- 4277.9 lb/ft / 5800 N·m

- Turning Torque

- 1253.9 lb/ft / 1700 N·m